It’s been years since I have posted any new projects on my blog – it’s not due to a lack of inspiration or ideas, rather I was too busy to build any new projects – or publish what I was working on. In the meantime my interests and experiences have evolved towards fields that I have been less involved in during the past years, and the general lack of time has made me rethink some of my building practices towards more time-efficient solutions.

Headphones and Speakers

While like most of my generation I have experienced first

hand the advent of mobile audio in the form of the first “Walkman” devices

(cassette players with and without FM radio) and thus grew accustomed to using

headphones, I was never particularly taken by headphones listening – always preferring

speakers. Over the years, this preference has basically cost me a lot in terms

of musical pleasures not experienced: everyone can hear what (and how loud) you

are listening when you use speakers, which implies that your family willing or nilling

takes part of your musical and audiophile life. If your tastes include rather

hermetic music, or hard bop, post bop, modal, classical – you name it,

basically whatever is not mainstream commercial… in other words not suitable

for everyone and not necessarily acceptable to others – you will likely listen

to less music than you might have had, or will have to avoid some of the music

you like. That’s where headphones enter the life of the regular music lover and

audiophile.

The main reason why I prefer speakers to headphones is space

– the music otherwise being confined to one’s head and thereabouts.

Furthermore, the subjective sound quality being (perceived as) far higher with

speakers – which might be a surprise to those who are aware or at least

convinced that headphones are far superior in terms of transducers (no need for

crossovers, little or no limitations due to available power, etc). Well, most

probably that was due to the fact that we used to listen to headphones

connected to the headphones connectors of our (integrated) amplifiers and

receivers, or CD players and cassette decks: simply put, driven by a handful of

small transistors, or op-amps. The advent of the new generation of often USB capable

DACs, of which some were marketed as headphones amplifiers, did little or

nothing – for me, at least – to change the perception of headphones sound

quality as inferior to speakers in a good system. Well, I guess the words “good

system” are the key to this perception – just like trying to compare some

integrated solid state amplifier with a good (or much better than good, for

that matter) tube preamplifier matched to some SE tube amps, with good cables

to boot and all the possible amenities – on the same set of speakers. I needed

to listen to more music, and it became obvious to me that there must be a way

to equalize the perceived sound quality between speakers and headphones – let’s

search for it in the missing link, the amplification.

Design Choices

Headphones do not need a lot of power – so far I have not

had any planar magnetic headphones, but even these should probably do well with

a couple of good watts… while most headphones are actually rated for less than

2W of power (i.e. they can handle that much power before being destroyed –

assuming that your ears are not involved in the ordeal as they would make it

painfully obvious that the power is too high).

What headphones do need is a high quality amplifier with low

(lowish, actually) output impedance. Besides the most obvious choice of active

element (tubes and solid state), and the quality of the power supply, passive

elements are also relevant to the perceived sound quality of the amplifier –

most notably capacitors and transformers. I guess it’s more than obvious that I

would not choose solid state active elements to build an amplifier for my

headphones, and with tubes there are basically 2 design options – with or

without output transformer.

While there are lots of amp designs and ideas all around us

on the net when it comes to using tubes to drive headphones without an output

transformer, almost all reasonably feasible (and repeatable in terms of

performance) alternatives must use a coupling capacitor between the headphones

and the amplifying stage. I prefer to avoid coupling capacitors in the signal

path, and my designs are centered on using the least number of gain stages and

therefore coupling caps. Furthermore, when it comes to headphones, the values

of the coupling caps have to be rather high if one is after a reasonable

response in the lower frequencies: this is particularly true for most “modern”

headphones which tend to be anywhere between 32 and 150 ohms impedance. The

large value implies the use of electrolytic capacitors: while it is possible to

parallel film caps to some extent, this will almost always end up in a very

costly and physically large compromise. Caps will tend to leak, and that’s just

another problem one is facing with output caps in a headphone amp. I have the

feeling that the headphones are not really safe with a capacitor coupled

output, although that is probably irrelevant to most: you only live once, so

who cares…

As I already mentioned, most currently available dynamic

headphones are between 32 and 150 ohms impedance, where above 80 ohms the

choice becomes rather slim, at least in terms of variety. While these lower

impedance headphones are relatively easily driven with solid state devices, they

represent a taxing load for tubes and the possible solutions are either

push-pull circuits, or the usual highly inefficient cathode follower

compromises that are quite good at driving higher impedance headphones (300 -

600 ohms) but cover the fact that they are struggling to drive lower impedance

headphones regardless of the inefficient high idle current draw and relatively

high output power (relatively high – that is in terms of headphones power

handling capabilities).

Some well-known amps and kits resort on 6080 or 6AS7 in

cathode followers drawing high currents and running their cathode resistors

rather hot: I have considered this option with 2k 25W cathode resistors and was

not happy with the high current that would have to be drawn, the heat generated

by these cathode resistors, the compromise when driving anything else than high

impedance headphones – and last but not least, the output capacitors. OK, let’s

put this straight – amplifier size or power consumption was the least of my

concerns; I do not like unnecessary heat in an amp, and I do not like output

coupling capacitors – but what I hate most is the compromise involved. While I

own several headphones, most are low or lower impedance, and I guess most DIY-ers

and audiophiles are facing the same choice of headphones. Last but not least, I

like universal solutions (does the

word ring some bell?) and dislike compromises that can be avoided.

RH Amplifier – Headphones Edition

Once we leave the output capacitor path behind, the only way

to go is with an output transformer. While some would consider the output

transformer as another compromise in quality, similar to the capacitor, I would

beg to differ. The transformer does not leak, unlike the capacitor, and

headphones are safe unless abused: the only regular problem that comes to mind

is the pops and clicks when powering up or powering down the amplifier, but

that can be avoided in more ways than one. The limitations of output

transformers are known, and in this case due to the fact that headphones do not

require a lot of power, can easily be solved with larger cores than strictly

necessary. A core that would be good for a decent 5W SE amplifier is more than

good for a headphones amplifier that will in most cases deliver less than ½W of

power. On the other hand, transformers can be rather universal devices that

offer flexibility – just like the 4, 8, and 16 ohm taps on some output transformers,

there can be 32, 64, 128… ohm taps on the output transformer for headphones,

matching the impedance of the headphones at hand, or better – the impedance

groups of headphones.

Now that the decision is made – go with an output

transformer – an amplifier is needed. Well, in my case that can only be an RH

amp, otherwise I would not be true to myself. Over the years I had several

times been asked if the RH84 could be used as a headphones amp, provided the

appropriate output transformer is installed – and I have replied that it most

certainly can, but it was not designed, or optimized, for this role. The

purpose of the RH84 is to drive speakers with as much power as can be had from

the EL84 while not sacrificing the sound quality – actually, trying to solve

that design task better than most other amps.

For the headphones RH amp, I chose to design something “new

and different”, although the resemblance to my other designs is striking. This

amp does not need to produce more than a couple of Watts of power, but needs to

yield excellent sound quality, and absolutely needs to be quiet – i.e. no noise

is allowed because the headphones being on the listener’s ears are quite

sensitive to noise and hum. Last but not least, the optimization needs to be

easy, taking into account the intrinsic differences between the imperfect

devices that tubes are, and the variations possible even within the same batch.

One additional element that needed to be taken into account

is the lowest sensitivity possible without resorting to additional volume

potentiometers, while the amp needs to be able to easily accommodate various

use cases with simple modifications. Lowest sensitivity possible – this implies

that while it might be beneficial for a low power SE amp to get to its full

power of 3W with an input of 0.775mV RMS, this would be totally impractical for

the same SE amp used as a headphones amp. As I said several times already, this

amp will not be used at 2W output power by most users!

The design centers around the 6080/6AS7 tube which is a dual

triode just like the ECC81 or the 6SN7, but the two triodes inside the envelope

have 12W anode dissipation each, and mu is very low – lower than 2A3 or 300B.

Obviously, the low sensitivity requirement excludes all the usual pentodes that

come to mind - EL84, 6V6, and the

smaller “siblings” like EL85 or EL95 which can still be found and had at low

prices – although all of these tubes would have more than enough power for the

task. Even if those pentodes were used as triodes (something that I personally

don’t do) their resulting mu as pseudo-triodes would still be too high. The

2A3, 6BG4, or 300B might be used, and would probably be capable of interesting

results – but they are all directly heated and thus would require additional

attention (and circuitry) to avoid filament hum. The 6080/6AS7 tubes are rather

plentiful and therefore still cheap, and will not require any additional

attention to heating – being indirectly heated triodes.

The driver is the usual ECC81 that I use for all my other RH

amps – I guess by now it does not need any introduction. Let me just reiterate

that this tube has a relatively high mu (reasonably high internal impedance)

combined with a relatively high transconductance – two characteristics that

make it especially suitable for the role it is supposed to have – driving the

output tube to desired results.

As mentioned at the beginning, the lack of time has driven

me towards different solutions than previously adopted: installing sockets and

doing a hard-wired installation might be the best solution for most people,

provided they had the time to do it. Additionally, while a hard wired

installation is expected to yield better sound quality and last longer, it is

quite impractical for servicing and adaptations, let alone re-use or recycling

in other projects. On the other hand, my recent preamplifier revalidation has shown

that even PCBs I have drawn and etched manually have lasted more than a decade

without any problems whatsoever, and continue to perform well in spite of the

servicing and modification changes (change of component values to suit other

tubes). Thus when building a new preamplifier I have redesigned the PCBs and

this time had them etched instead of doing it myself.

In accordance with the experience gained using the old preamplifier for more than a decade, and having just built a new version, I have

decided to design an amplifier board that I named RH6080 – generally suitable

for application of most noval tubes as drivers, and the 6080/6AS7 family of

tubes in the output position octal socket. The two channels are basically

dual-mono except for the common ground on the board, and the fact that the

tubes are dual triodes: in theory, even the B+ could come from a different

source or be of different value, although that is highly unlikely.

I can use the same board to build other projects that I have

in mind – an 8W SE amp for loudspeakers, PP RH amps – and even a driver

amplifier that can push large output tubes into class A2… projects awaiting to happen in the future.

Performance and Optimization

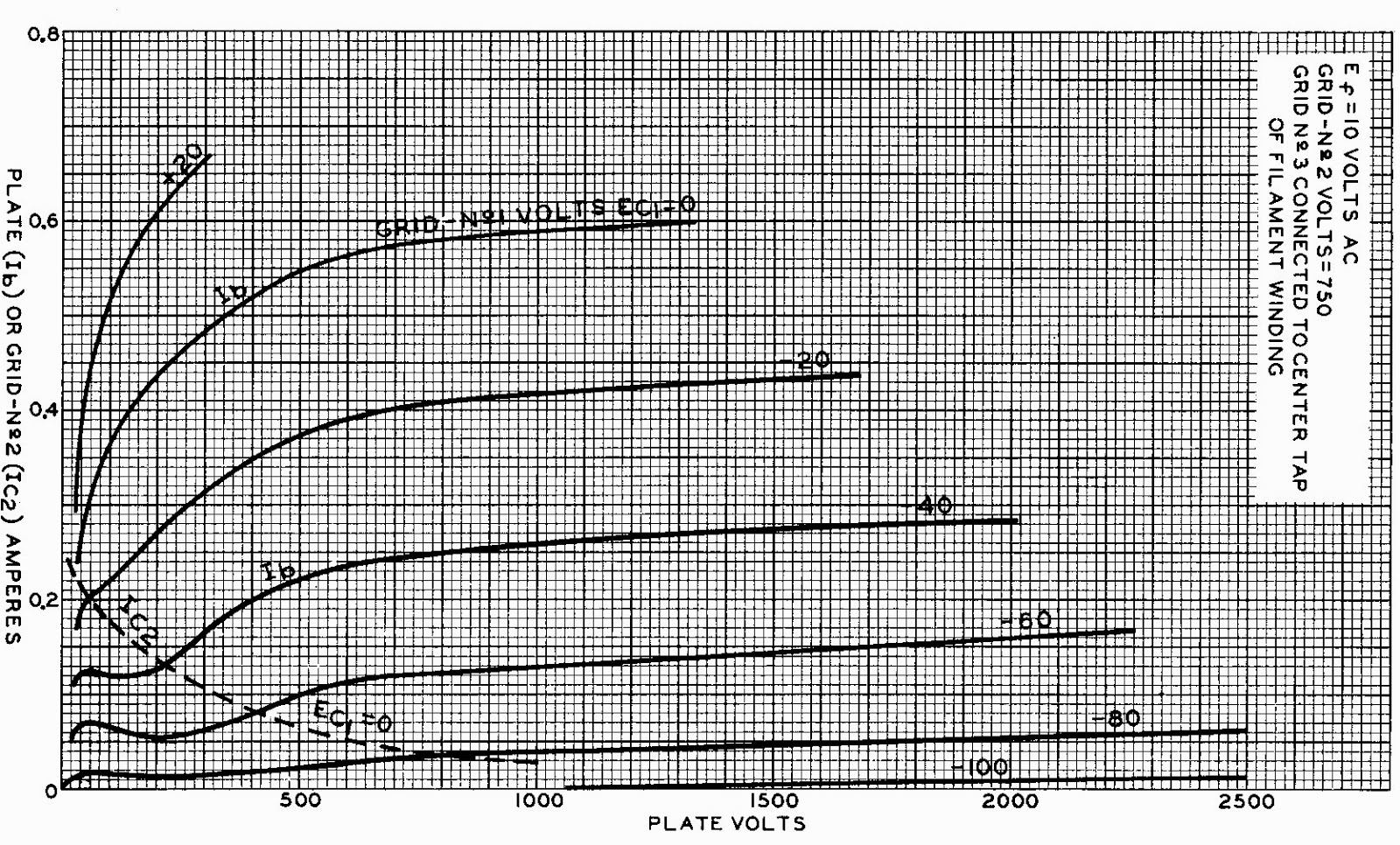

As shown in the simulation, this amplifier is capable of

3.2W output power with an input of 2.5V RMS. As such, with an appropriate

output transformer it could be used to drive speakers – rivaling classic SE amps

with 2A3 output tubes, usually specified as 3.5W output power. The 6080/6AS7

output impedance is lower than that of the 2A3, and combined with the RH

specific feedback – this translates into quite low output impedance for an SE

amp: what DIY-ers who have built RH amps have previously experienced with the

amps they built would be adequately replicated by this amp. Simulations are

just as good as the models used, and the models I am using both for ECC81

(accuracy comparison shown in the RH813 post) and the 6080/6AS7G are as

accurate as possible. By that I mean – the models were created based on a sets

of curves shown in the datasheets – to get the results with 100% accuracy one

would have to generate curves from the batch of tubes used, and create models

based on these curves. The accuracy achievable with datasheets curves should be

considered as “as accurate as possible” – unless one is in the “laboratory

measurements” hobby as opposed to the “designing and building amplifiers”

hobby.

This amplifier is supposed to be used as regular amplifier

for loudspeakers – the only difference being that headphones are connected to

it instead of the loudspeakers. Therefore, there is no volume potentiometer

except for the one on the preamplifier. My current preamplifier has 20dB of

line stage gain, giving it a reasonably ample range of volume adjustment with

my power amplifiers into my speakers, where the amps are not particularly

sensitive, and the speakers are reasonably efficient. When operating the

RH6080HE I have found that the volume adjustment range on the preamplifier pot

is twice as limited – basically, at 9 o’clock the volume with most headphones

is at the limit of my comfort zone in terms of loudness, i.e. output power. In

practice, this means that with the addition of a volume potentiometer and

eventually a selector it can be used without a line stage preamplifier, or

connected to the tape output of the preamplifier (without line stage gain).

A slight modification to the input circuitry where the

cathode resistor coupling cap is removed decreases input sensitivity further to

almost 3V RMS needed for full output, while the remaining parameters are the

same – this increases the range of volume adjustment on the potentiometer, and

makes it easier to find the adequate volume for listening. I guess in this case

use without a preamplifier as explained above is still borderline possible and

will depend on the output voltage of the source used – a CD or DAC at 2V RMS

output should be amply sufficient to exceed comfort zone volumes with

headphones, but lower output sources might lead to insufficient volume and/or a

lack of fullness in the sound.

This is a single ended, i.e. SE amp – thus absolutely

suitable to drive any headphones without the need for any strange or

non-standard connectors. Nevertheless, as the output transformers totally

isolate the headphones from signal or power ground, and even the left from the

right channel, I have chosen to adopt as standard a 4-pin XLR socket, basically

the same as used by some manufacturers to connect headphones in balanced mode.

Needless to say, I have chosen to implement the same pin connection standard as

used by the manufacturers, mainly to simplify potential issues with cables

compatibility.

Balanced headphones connection requires a separation of

ground returns between channels, hence the need for 4 connections instead of

the usual 3 (common ground). Thus a pair of headphones configured for balanced

connection can easily be connected to this amplifier, as the grounds are

galvanically isolated – although obviously they will be driven in single-ended

mode since the amplifier is SE. In order to connect headphones with regular

6.3mm jacks and 3 connections (common ground) an adapter is sufficient where

the ground connections are shorted: this might be even dangerous with a

balanced amplifier, but is absolutely normal with this SE amplifier. Therefore

I have decided against having an additional 6.3mm jack terminal next to the 4-pin

XLR and to use a custom-made adapter instead.

The knob visible on the facia of the amplifier is not a

volume potentiometer – rather a selector. The purpose is to choose the

secondary of the output transformer based on the impedance of the headphones

connected to the amplifier. While the type pictured is good enough for the task

and works fine in practice, it is sub-optimal and I suggest a better selector

is installed – besides mechanical stability the clue regarding it’s adequacy

for the task is declared current/power capability.

The Power Supply

The initial version was built with a rather simple CLC power

supply that would be suitable for an SE amplifier that drives speakers –

basically, if this amp was used to power loudspeakers, there would be no

audible hum or noise audible at 1m and even less from the speakers. But, this

amp is used with headphones, and absolutely all sound effects can be heard – down

to the eventual propensity to microphonics of some tubes (even the output

tubes), and this includes all sorts of hum that come to mind. As usual, I have

had no problems with the wiring or ground loops, but in the absence of music

clean low frequency (100Hz, twice the mains frequency) hum could be heard. At

that point it became clear that the power supply is either going to be large (marginally too large for the box in which I was building it),

elaborate, and expensive – or regulated.

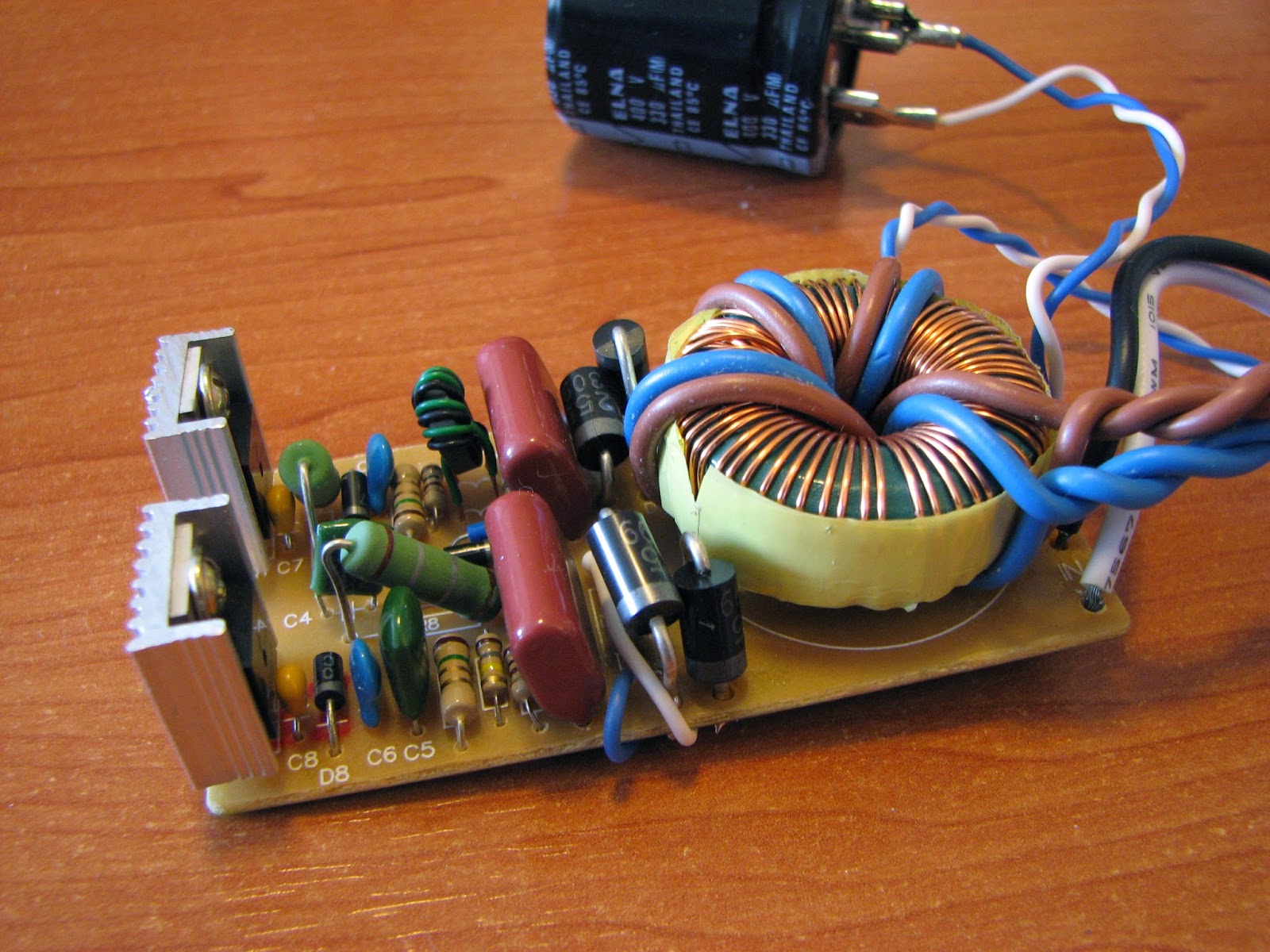

Having had excellent results with the power supply I have

recently developed for a new iteration of my classic preamplifier (some might

remember the RPA, not available on the net any more as the old site has disappeared),

I decided to modify the voltage setting resistors ratio to match the needs of

the RH6080HE and populate a spare PCB etched for the preamplifier project that

I had at hand. It took me literally minutes to build it, as opposed to hard-wiring

capacitors and finding a way to keep them fixed… This power supply works perfectly with the

phono stage, both in terms of hum and noise, as in terms of perceived sound

quality.

Needless to say, as expected, the amplifier became dead

quiet – it all boils down to tubes quality now, as some driver tubes (ECC81)

might be less quiet than needed – and even some 6AS7 can be noisier than a

perfectionist would accept. The power supply uses a hybrid bridge composed of a

dual rectifier tube and two solid state diodes – the rectifier tube is slower

and dictates the behavior of the solid state diodes, with the result being

sonically equal to what the rectifier tube would yield in a pure tube

rectification circuit. The active pass element is a TL783, a device similar to

the LM317 but with a much higher input-output voltage differential of 125V.

Another difference is the pass element which in the TL783 is not bipolar rather

FET. The same circuit can be built with an LM317, but in some circumstances the

input-output voltage differential might be higher than 35V (highly unlikely but

possible) most probably killing the LM317 instantly… no harm would happen to

the tubes, obviously, but the hum would immediately rise to unacceptable levels

pointing out that something needs to be done about it… Another difference is

the quality of the TL783, which unlike most LM317 is not noisy. The difference

in price is irrelevant in DIY terms and the TL783 should be relatively easy to

come by.

Some would probably object to the solid state regulator, as

the solid state pass element is expected to mask the “sound” of the tube

rectifier. As I already said, this power supply has proven its worth in the

preamplifier project, and rectifier tube rolling with this power supply is more than effective in

fine-tuning the sound. The only issue for tube rolling might be the possibly

large difference in output voltage between different rectifier types (actually,

the difference in diode voltage drop) – precluding the use of 5R4 and 5Y3 tubes

in this circuit (input-output differential too low and the regulator is not

working properly, with high hum as a result). Of course, that can be

circumvented with a higher secondary AC voltage (for instance, 360V instead of

330V) but in that case when using more efficient rectifiers like the 5Z4 the

input-output differential across the regulator element will increase to

probably 30 or 40V, which combined with 100mA current draw for the amplifier

circuits yields 3-4W of dissipation – precluding the use of more efficient

rectifiers and limiting reasonable operation with a higher voltage secondary to the 5Y3 or 5R4 rectifier tubes. In that case, a

good heatsink capable of at least 5W dissipation is necessary: I prefer keeping the dissipation below 1.5W. It goes without saying that both the

TL783 used in the power supply, and the regulators used as current sinks below

the cathodes of the output tubes must be heatsinked, although the heat-sinks do

not need to be particularly large (adequate for up to 2W dissipation).

The Output Transformers and Sound Quality

Well, so far so good – it’s just a regular RH amp with

output transformers that are adequate for headphones, and can be build on PCBs –

making it esier for DIY-ers… but most SE output transformers are actually designed

and manufactured for loudspeakers, with 4 and 8 ohm taps. They are not adequate

for 32 ohm headphones, let alone high impedance types at 300 or more.

The output transformers used for this project were

manufactured by Heyboer in the US based on project requirements – and provided

by a fellow DIY-er: Larry Granger. I

would like to thank him for finding the subject interesting, and for his kindness

in providing the output transformers – without those, the project would just be

dead drawings on (electronic) paper.

The primary was chosen to be 5k – this is perfectly suitable

in general for tubes drawing 40-50mA, and a value generally suitable for most

low power pentodes and tetrodes, like the EL84 or the 6V6. While this value seems

too high for use with 6080/6AS7, the assumption is not particularly correct.

The output tube in this circuit is used at a rather unusual operating point,

constantly drawing 50mA and having just above 200V across the tube (cathode to

anode). The output tube in practice operates at around 10W anode dissipation,

which is absolutely acceptable for this type of tube and guarantees a long

operating life. On the other hand, output power maximization is not necessary –

and it is already done with the particular feedback applied which includes the

characteristics of the driver tube.

The core of the transformer would be absolutely suitable for

a high quality SE amplifier in the range 3-5W, and most manufacturers would

market it as a 10W core: thus it is expected to behave very well in terms of

bandwidth. The higher than usual primary impedance for the tube, and the low output impedance of the

circuit mean that with this transformer there should be no bandwidth

constraints, particularly at 1W output power and below. While not having any

planar magnetics to try, I expect that even the slightly higher power

requirements of such headphones would be served nicely.

The secondary windings were chosen to be multiples of 32

ohms – 32 ohms being the de-facto standard value with headphones nowadays. Thus

the values are 32 – 128 – 256 – 512 ohms, and as such will accommodate a wide

range of headphones from 32 to 600 ohms. Connecting 600 ohm headphones to the

512 ohm secondary will result in lower primary impedance seen by the output

tube as 4.2k instead of 5k – but as explained above, this tube and the circuit

can easily handle 20% differences in primary load, while 450 ohm headphones

will again fit the 512 ohm tap very well. Similarly, connecting 300 ohm

headphones to the 256 ohm tap is absolutely fine. Most 70 or 80 ohm headphones

actually show impedance charts around 100 ohms, and they can be well served by

the 128 ohm tap, just like the 150 ohm headphones. I am deliberately not

mentioning the brand names of the “usual suspects”, and I expect most

headphones enthusiasts know well which brand still manufactures 300 and 600 ohm

headphones, and eventually proposes new “improved” models of 150 ohm impedance…

Last but not least, the sound quality: much better than

expected, actually. While my amplifiers perform very well in my room driving the

reasonably efficient speakers that I use, with the RH6080HE power is not a

relevant topic, at least in terms of loudness and dynamics. Having much more

power than needed imparts an ease and effortlessness in the presentation

of music, and the most important characteristics that I have found is

what I was missing most with headphones – space, or rather the sense of space.

It is common knowledge that open headphones convey a better sense of space,

frequently at the expense of less depth and definition in the bass notes. With

this amplifier, I have found improvements on both: closed headphones have an excellent

and unexpected rendition of space, while even those bass-heavy among them show

a very controlled low register. On the other hand, the sense of space with open

headphones is amazing, while the rendition of bass notes is so effortless and

well defined that it easily rivals listening on loudspeakers.

More importantly – how does this amplifier compare to

commercial alternatives? Well, first of all, I am not aware that there are many

commercially available tube amps with output transformers and multiple

secondaries – and not having listened to any such amps, I can only believe that the

difference is proportional to what can be had when a “regular” loudspeaker

driving RH amp is compared to commercial alternatives of similar power. On the

other hand, there is literally no comparison with most if not all commercial

solid state device powered alternatives that I have had the possibility to try: the difference in

sound quality is quite pronounced and it becomes quite obvious that the tube amp is in a league of its own. But, as a good friend nicely puts it – one can take along most of these amps and DACs in one’s pocket and carry them along enjoying music

everywhere, while I cannot take this amplifier, rather heavy and the size of a

regular SE amplifier, and use it on the go. Still, the purpose of this

design has never been portability, but sound quality rivaling listening to a

good system with loudspeakers – and that goal has been amply achieved.